Where is the centrifugal dust collector fan suitable for use ?

A centrifugal dust collector fan is suitable for use in various industrial and commercial applications where there is a need to collect and remove airborne dust particles.

Some common areas where centrifugal dust collector fans are used include:

- Woodworking: These fans are commonly used in woodworking facilities such as sawmills, furniture manufacturing plants, and woodworking shops to capture and remove sawdust and wood particles from the air.

- Metalworking: Centrifugal dust collector fans are used in metalworking industries like foundries, metal fabrication shops, and welding operations to extract metal dust, fumes, and particles generated during cutting, grinding, and welding processes.

- Mining and Quarrying: In mining and quarrying operations, where dust and particulate matter are generated during activities like drilling, blasting, and crushing of rocks, centrifugal dust collector fans help to control and remove the airborne dust.

- Chemical and Pharmaceutical Industries: Industries that handle powders, chemicals, and pharmaceuticals often use centrifugal dust collector fans to maintain clean and safe working environments by capturing and controlling airborne contaminants.

- Food Processing: In food processing plants, centrifugal dust collector fans are employed to collect and remove airborne particles such as flour, sugar, spices, or other food ingredients, ensuring cleanliness and preventing cross-contamination.

- Cement and Construction: Centrifugal fans are commonly used in cement plants, construction sites, and other construction-related activities to control and remove dust and particulate matter generated during cement production, concrete mixing, and other construction processes.

- Power Generation: Centrifugal dust collector fans are utilized in power plants, particularly in coal-fired power plants, to capture and control the fly ash and other particulate matter produced during combustion processes.

These are just a few examples of where centrifugal dust collector fans can be suitable for use. The specific application centrifugal dust extractor fan and requirements will determine the type and size of the fan needed for effective dust collection.

Can you provide more information about the different types of centrifugal dust collector fans available?

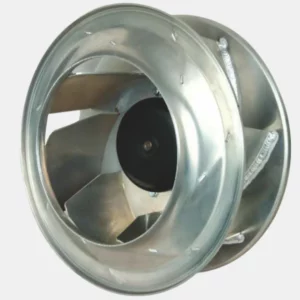

There are several types of centrifugal dust collector fans available, each designed to meet specific requirements and applications. Here are some common types:

- Forward-Curved Blades Fans: These fans have blades that curve in the direction of rotation, forming a shallow S-shape. They are efficient and suitable for low to medium pressure applications. Forward-curved blade fans are commonly used in HVAC systems and general ventilation applications.

- Backward-Curved Blades Fans: These fans have blades that curve away from the direction of rotation, forming a backward shape. They are highly efficient and suitable for high-pressure applications. Backward-curved blade fans are commonly used in dust collection systems, industrial ventilation, and other applications where there is a need for high static pressure.

- Radial Blade Fans: Radial blade fans have straight blades that extend radially from the center of the fan. They are suitable for medium to high-pressure applications and can handle particulate-laden air. Radial blade fans are used in applications such as material handling, pneumatic conveying, and dust collection systems.

- Airfoil Blade Fans: Airfoil blade fans have blades that resemble the shape of an airfoil, similar to those used in aircraft wings. They provide high efficiency and are suitable for applications requiring high airflow and low noise levels. Airfoil blade fans are commonly used in HVAC systems, cleanrooms, and other applications where a balance between airflow and noise is crucial.

- Backward-Inclined Blade Fans: These fans have blades that are inclined backward against the direction of rotation. They offer high efficiency and are suitable for medium to high-pressure applications. Backward-inclined blade fans are commonly used in dust collection systems, industrial ventilation, and air pollution control applications.

- Centrifugal Fan Wheels: Centrifugal fan wheels are designed specifically for dust collection systems. They consist of a rotating wheel with backward-curved blades that accelerate the air and direct it towards the outlet. These wheels are available in various sizes and configurations to match specific airflow and pressure requirements.

It’s important to note that the selection of a centrifugal dust collector fan should consider factors such as the volume of air to be handled, pressure requirements, particulate characteristics, efficiency, noise levels, and system design considerations. Consulting with an expert or supplier specializing in industrial ventilation and dust collection can help determine the most suitable fan type for a specific application.