Make Concrete Blocks For A Living With A Solid Foundation

Making concrete blocks for a living can be a profitable and rewarding business.

Here are some steps to help you establish a solid foundation for your concrete block-making business:

Research the market: Conduct market research to determine the demand for concrete blocks in your area. Consider factors such as construction trends, building codes, and the availability of local suppliers.

Develop a business plan: Create a business plan that outlines your goals, target market, marketing strategies, financial projections, and operations plan. This will help you stay organized and focused as you start and grow your business.

Choose a location: Choose a location for your business that is easily accessible to suppliers and customers. Consider factors such as zoning laws, availability of utilities, and proximity to transportation.

Obtain necessary permits and licenses: Obtain the necessary permits and licenses to operate your business legally. This may include a business license, zoning permit, and environmental permits.

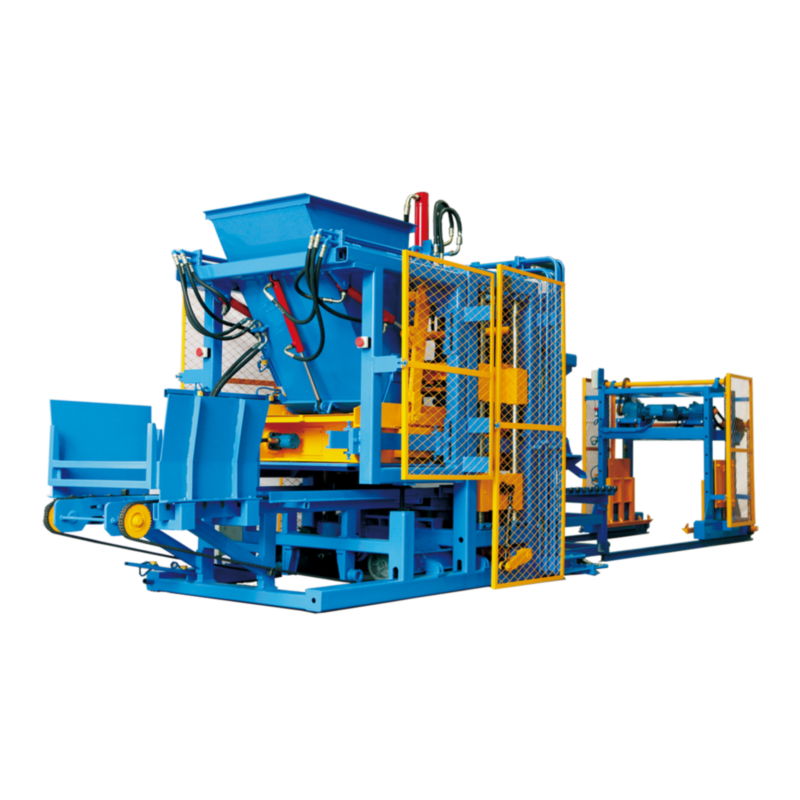

Purchase equipment and supplies: Purchase the equipment and supplies you need to make concrete blocks, such as a block-making machine, molds, cement, China concrete block making sand, and aggregate. Consider purchasing used equipment to save money.

Hire employees: Hire employees to help you with the manufacturing process and other aspects of your business, such as sales and marketing.

Develop a marketing plan: Develop a marketing plan to reach your target market. This may include advertising in local newspapers, participating in trade shows, and building relationships with contractors and builders.

By following these steps, you can establish a solid foundation for your concrete block-making business and work towards a successful and profitable venture.

How can I determine the appropriate pricing for my concrete blocks?

Determining the appropriate pricing for your concrete blocks is a crucial step in running a successful business.

Here are some factors to consider when pricing your concrete blocks:

Cost of materials: Calculate the cost of the materials needed to produce each concrete block, including cement, sand, aggregate, and any additives.

Labor costs: Consider the cost of labor, including the wages of employees involved in the manufacturing process.

Overhead costs: Take into account the overhead costs of running your business, such as rent, utilities, insurance, and equipment maintenance.

Market demand: Consider the demand for concrete blocks in your area and adjust your prices accordingly. If the demand is high, you may be able to charge a higher price.

Competition: Research the prices of your competitors to ensure that your prices are competitive.

Profit margin: Determine the profit margin you want to achieve and adjust your prices accordingly. Be sure to factor in unexpected costs and potential price fluctuations.

Value proposition: Consider the value proposition of your concrete blocks compared to your competitors. If your blocks offer unique features or benefits, you may be able to charge a higher price.

By considering these factors, you can determine an appropriate pricing strategy for your concrete blocks that will help you cover your costs, make a profit, and remain competitive in the market. It may also be helpful to periodically review and adjust your prices as market conditions and production costs change.