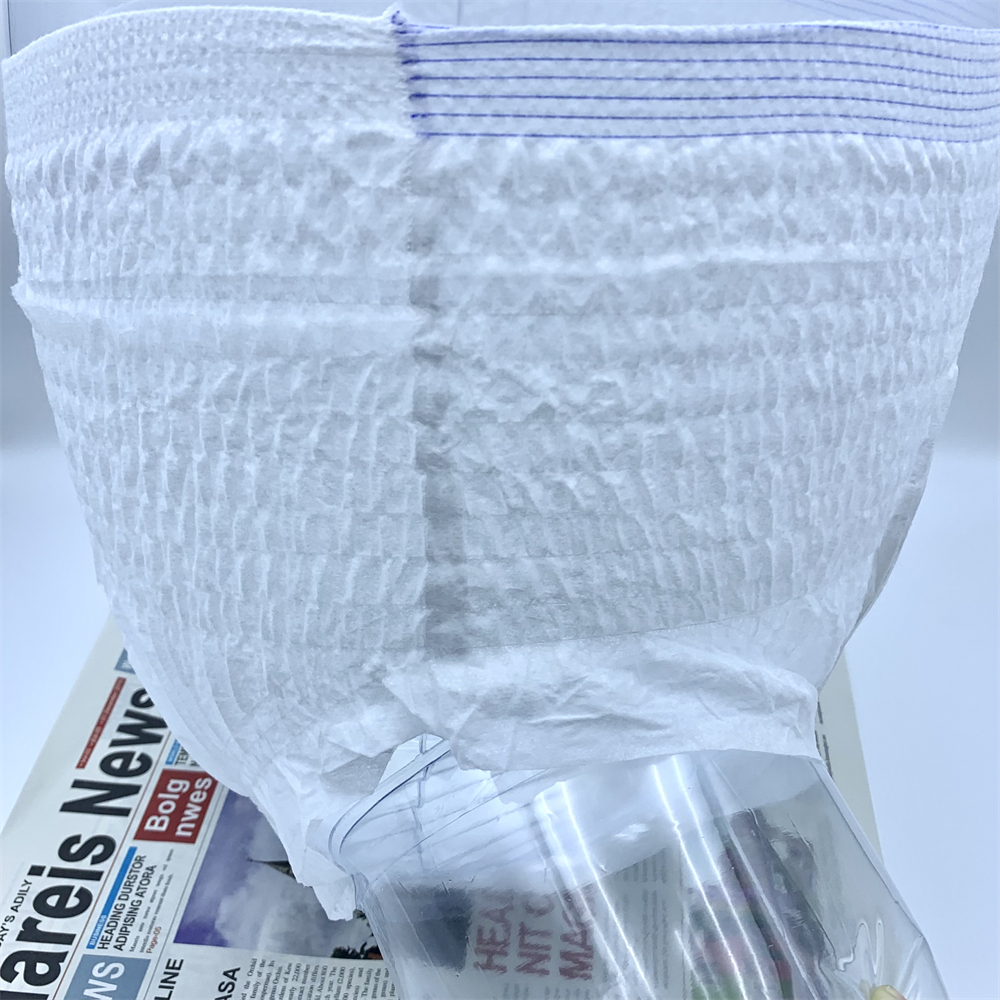

Which material is the most durable for adult diaper?

Adult diaper suppliers use the most durable materials include:

Laminates

Plastic or polyurethane laminates provide waterproofness and help contain urine within the diaper. They are durable, tear resistant and abrasion proof. Laminates are used as an outer layer or barrier in most disposable diapers.

Microfiber

Microfiber fabrics are very absorbent, soft and durable. They can withstand repeated use and laundering without damage. Microfiber is used for inner layers and outer covers of diapers to provide absorbency along with strength.

Polyester

Polyester materials like spunbond nonwovens are durable, abrasion resistant and long-lasting. They can form the inner and outer layers of a diaper without tearing or ripping easily. Polyester diapers tend to maintain their shape and absorbency through multiple uses.

Elastic

Elastic materials like spandex, latex and polyurethane elastic bands provide stretch and form-fitting closure for diapers. They are durable enough to retain elasticity even after repeated fastening and re-positioning of the diaper.

Coated fabrics

Coatings of polyurethane, latex, PVC etc. are applied to materials like polyester or cotton fabrics to make them more durable and waterproof. Coated fabrics are strong, tear proof and chemical resistant which is suitable for diapers.

Heavy gauge materials

Thicker and heavier materials, even if non-durable by themselves, can stand up to repeated use without damage when used for diapers. Heavier polyesters, thicker microfiber fabrics and heavier laminates tend to be more durable.

Reinforcements

Features like elastic waistbands, adhesive tape closures, gel cores or polymer fillers are used to reinforce weak areas and provide extra strength, damage tolerance and leakage prevention in diapers. These reinforcements help extend the durability.

In summary, laminates, microfiber, polyester, elastic materials and reinforced/coated/heavy gauge fabrics are considered the most durable for use in disposable diapers. A combination of these materials is usually employed to achieve optimal durability, absorbency and leakage containment.